RENISHAW BLUETOOTH BALLBAR QC20-W

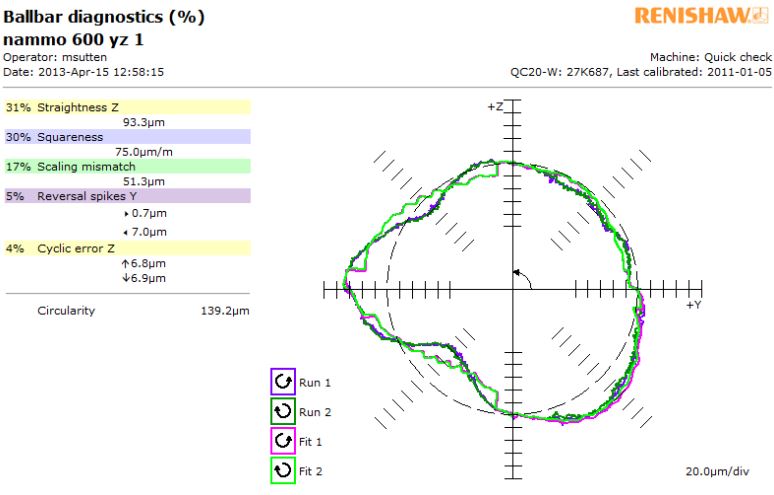

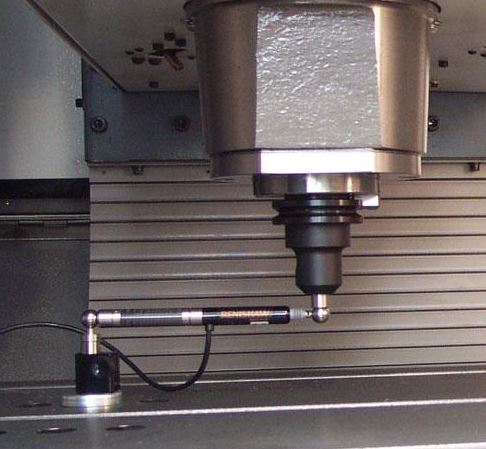

Besides the rental service,we also provide on-site Ball Bar check on your machine. The Ball Bar test is able to diagnose the machine inaccuracy at the same time ,check squareness, reversal spikes, cyclic error, scaling factor, servo mismatch and more.

The QC20-W system draws on Renishaw’s many years of experience with ballbar testing and offers significant performance and operational benefits:

-

Bluetooth wireless technology ensures no wire handling issues, closed door operation and reduced possibility for system damage.

- New hardware and software which allows a ‘partial arc’ (220°) test. This gives you greater test flexibility including

-

- improved Z axis testing (no custom fixturing required)

- tests where axis travel is limited (typically Z axis on machining centres and X axis on lathes)

- ability to test 3 planes from a single set up, using ‘partial arc’ tests for 2 of the tests and present a ‘volumetric analysis’

- Faster data reading for enhanced analysis on small test circle and high feed rates.

-

Enhanced software includes many new features for extended testing and greater ease of use.

Bluetooth wireless technology, totally revised electronics and enhanced test capability makes the QC20-W ballbar system even simpler to use and more powerful than its QC10 predecessor.

At the same time, test processes and results are compatible for QC10 users.

QC20-W specification

| Sensor resolution | 0.1 µm | 4 µin |

| Ballbar measurement accuracy* | ± (0.7 + 0.3% L) µm | ± (27.6 + 0.3% L) µin |

| Ballbar measuring range | ±1.0 mm | ±0.04 in |

| Sensor stroke | -1.25 mm to +1.75 mm | -0.05 in to +0.07 in |

| Maximum sample rate | 1000 Hz | 1000 Hz |

| Data transmission range (Bluetooth, Class 2) | 10 m typical | 33 ft typical |

| Operating range | 0 °C – 40 °C | 32 °F – 104 °F |

| System case dimensions (L x W x H) | 395 mm x 300 mm x 105 mm | 15.5 in x 11.8 in x 4.1 in |

| System case weight including kit contents | 3.75 kg (approx) | 8 lb 4 oz (approx) |

* also referred to as ‘radial measurement variation’

Valid 15 °C – 25 °C (59 °F – 77 °F)

L = length over which error is measured

i.e. Specification if measuring 10 µm error on machine ±0.73 µm

Specification if measuring 100 µm error on machine ±1.00 µm

Renishaw QC10 (Predecessor of QC20-W)