The position displays of the ND 500 series are suited for use on manually operated milling, drilling, boring machines and lathes with two or three axes. Due to the TTL encoder input, primarily the LS 328 and LS 628 linear encoders with a measuring step of 5 μm are used.

Description

With its sturdy housing and splash-proof membrane keyboard, the ND 500 is built for the workshop. The ND 500 series shows display position values, the soft-key row and other useful information on a monochrome graphic screen.

Functions

The most important functions are available quickly and directly via function keys. Soft keys with clear information in the local language enable you to make entries that fit your momentary situation. The distance-to-go display facilitates positioning. You approach the next position quickly and reliably by simply positioning until the display reads “zero.” The functions for each application are easily activated by parameter input. Special functions are available for producing hole patterns (linear patterns and circular patterns). You can easily switch between radius and diameter display when the position display is confi gured for turning. On lathes with a separate top slide, the sum display feature of the ND 523 allows you to display the saddle and top slides together or separately. Setting datums on a lathe part is particularly easy with the freeze tool position function and subsequent retracting.

Data interfaces

A USB interface enables the digital readout to transfer measured values and import

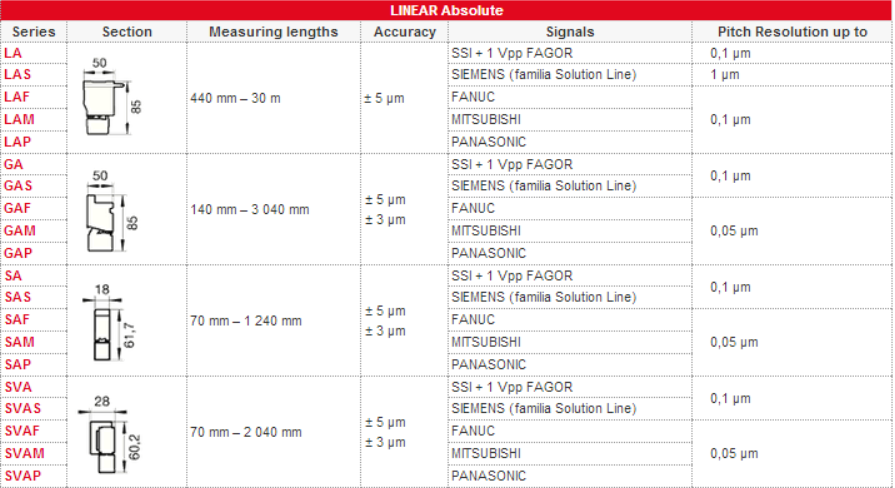

Linear Encoders

Fagor Automation uses two measuring methods in their absolute linear encoders:

• Graduated glass: Linear encoders with a measuring length of up to 3040 mm.

• Graduated steel: Linear encoders with a measuring length over 3040 mm.

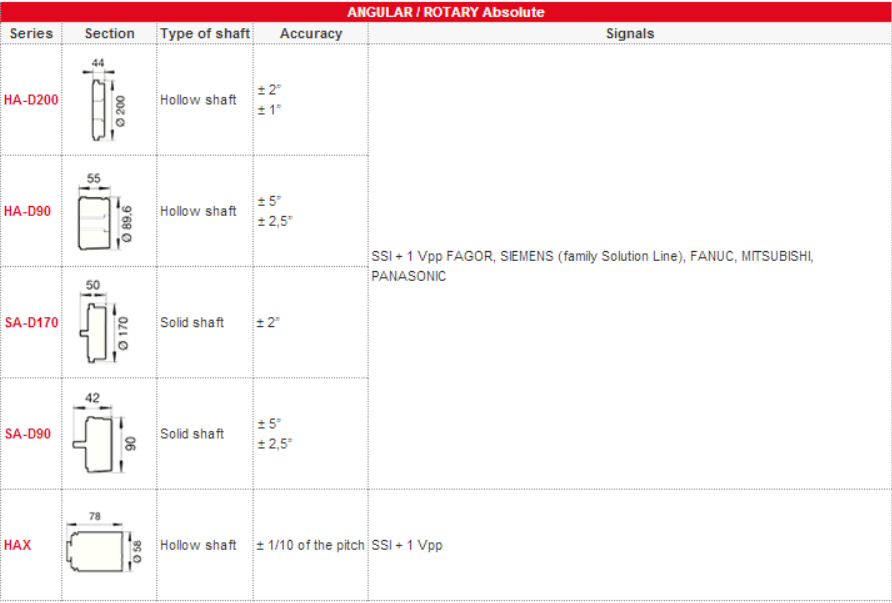

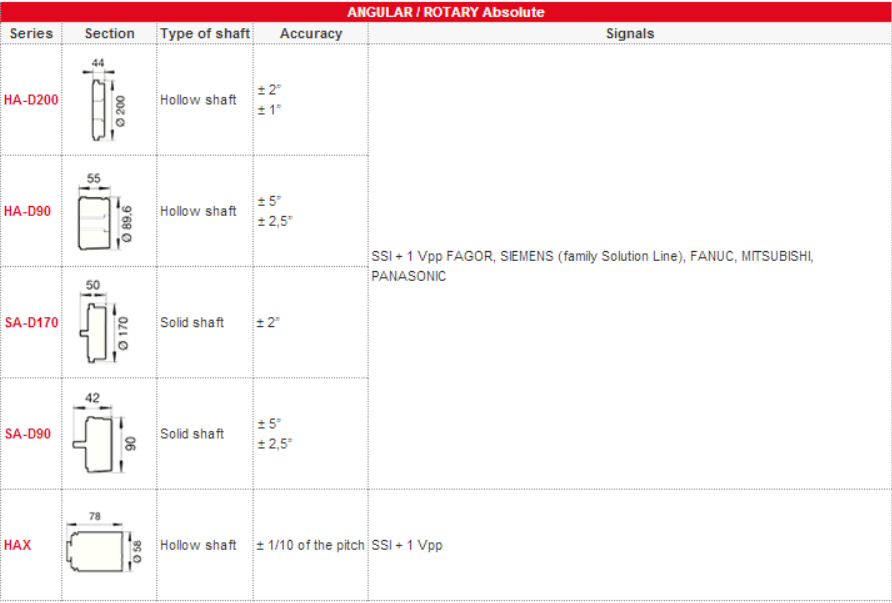

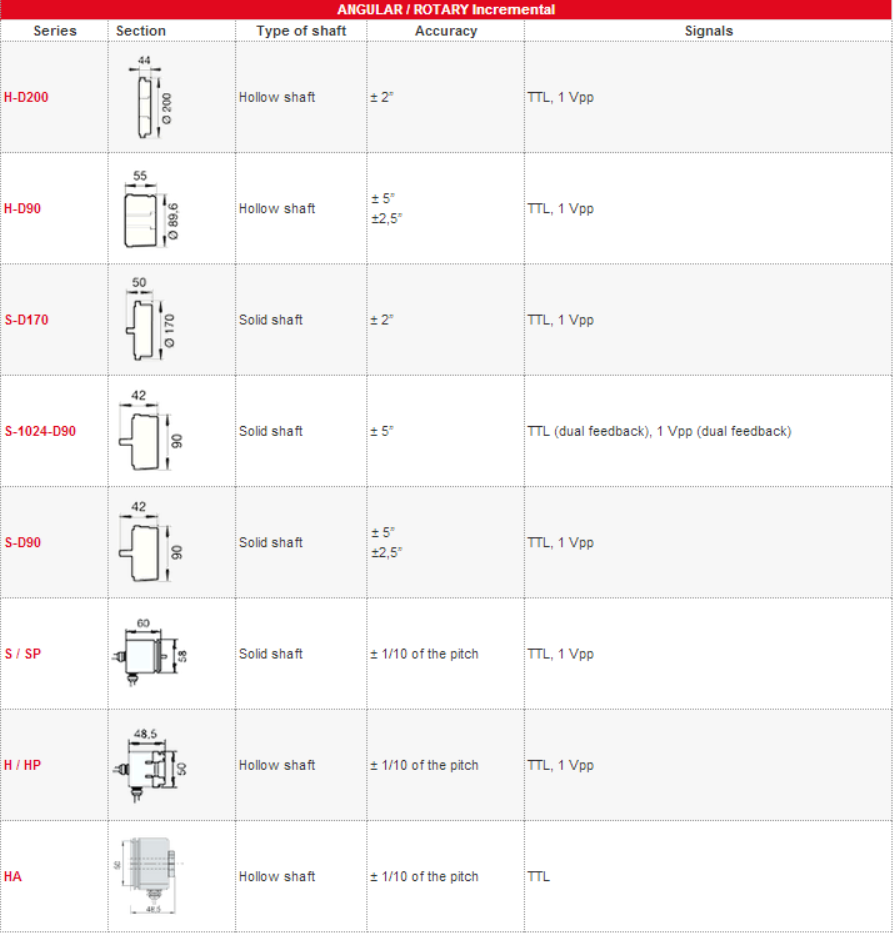

Angular and Rotary Encoders Fagor Automation uses the graduated glass measuring method in their absolute angular and rotary encoders.

This measuring method has two different graduations:

• Incremental graduation: Used to generate square incremental signals for systems that use digital position input and are counted internally by the reader head. Alternatively 1 Vpp analog signal is also produced based on the system requirement.

• Absolute graduation: It is a unique binary code which is imprinted along the measuring length of encoder.

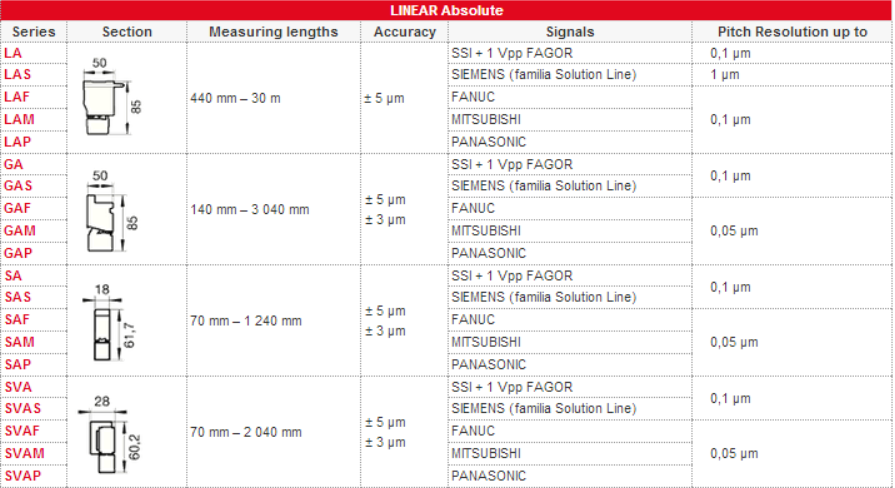

Linear Encoders

Fagor Automation uses two measuring methods in their absolute linear encoders:

• Graduated glass: Linear encoders with a measuring length of up to 3040 mm.

• Graduated steel: Linear encoders with a measuring length over 3040 mm.

Angular and Rotary Encoders Fagor Automation uses the graduated glass measuring method in their absolute angular and rotary encoders.

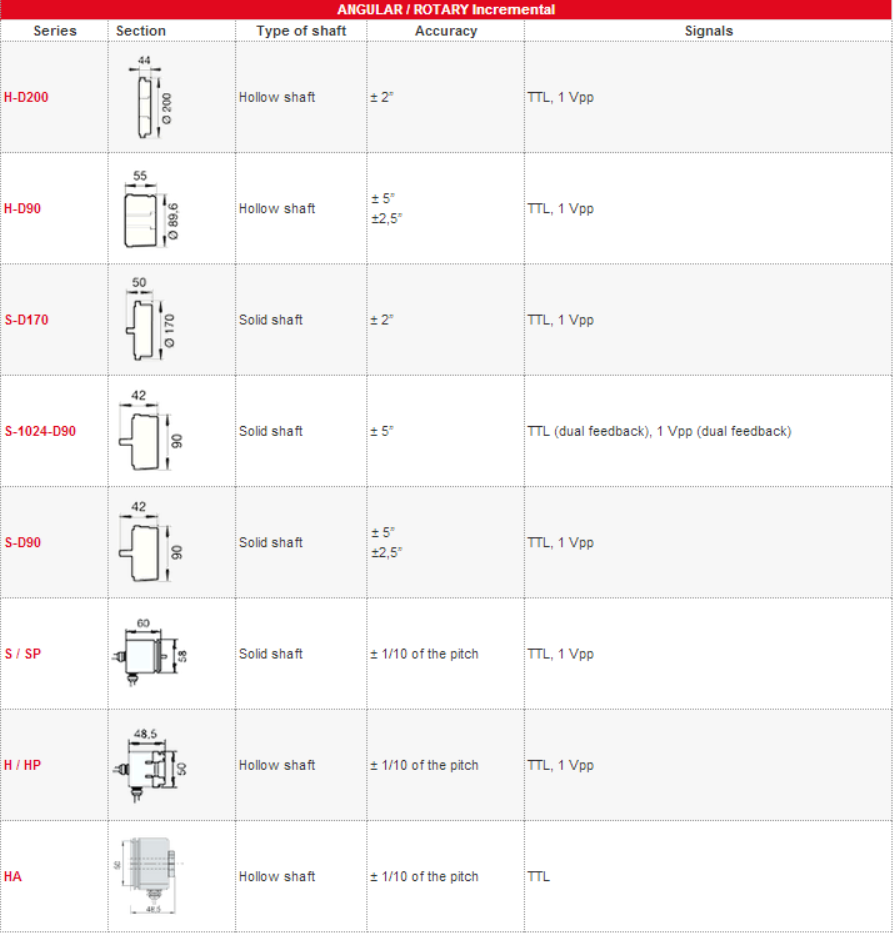

This measuring method has two different graduations:

• Incremental graduation: Used to generate square incremental signals for systems that use digital position input and are counted internally by the reader head. Alternatively 1 Vpp analog signal is also produced based on the system requirement.

• Absolute graduation: It is a unique binary code which is imprinted along the measuring length of encoder.

Features

- High performance, low cost 2 or 3 axis counter

- The KA counter has both mill and lathe functions, as well as standard functions

- Connectable with AT715 electromagnetic scales and AT100 series glass scales

Technical Data: Common

Scale input ports: 2, 3

Resolution: .000005″, .00005″, .0001″, .0002″, .0005″

(0.0001mm, 0.001mm, 0.002mm, 0.005mm,

0.010mm) (changeable with parameters)

Display: 7-digit LED and a negative [-] sign

Power supply: 100V-240V AC, 50/60Hz

Mass: 1.1kg (2-axis), 1.2kg (3-axis)

Optional Accessories

938140: Touch signal probe (shank diameter: 20mm)

935094: Touch signal probe (shank diameter: 32mm)

09CAB217: RS232C code out unit

64PMT114: Converter cable, RS232C to Digimatic SPC

Specifications

Mitutoyo’s DRO (Digital Readout) system integrates the AT100 Series Linear Scales (AT115/AT102/AT111/ AT112/AT181) with the K Series dedicated digital counters (KL/KLL/KM/KC/KS/KLD Counter), to offer accurate detection and display of axial displacements of machine tools and measuring equipment. The DRO system can be configured to best meet your specific application, such as turning, milling, or grinding. Choose a suitable combination of scale unit and counter. Scale units have diverse measuring length ranges and counters feature remote zero setting, switchable resolution, and multipurpose onetouch macro keys. The DRO system has superior ease-of-use and is reliable, both of which dramatically improve machining accuracy and efficiency. Mitutoyo strongly recommends implementation of the DRO system whatever possible.

With the DRO system, you can:

- Simplify machining procedure.

Procedures such as layout and setup can be completely omitted and simplified.

- Shorten machining time.

In addition to simplifying machining procedure, the operator is free from the drudgery

of measuring dimensions, positioning, and calculating feeding lengths, greatly shortening the time required for machining.

The more complicated the machining procedure, the more effective the DRO system is as a time-saver.

- Reduce errors.

The counter clearly displays the travel and the cutting depth, thereby reducing such errors as misreading of graduation,

miscounting of knob rotation, and miscalculation of dimensions. Dimensions are always consistent and are independent of

operators.

- Eliminate manual calculations.

The counter’s calculation function will display dimensions such as diameters of a rotating workpiece in design drawing notation if

machine feed knob is turned.

- Reduce machining costs.

Streamlined, labor-saving, and defective-free machining drastically reduces machining costs.

The DP1200 was designed specifically for long travel machine tools. It includes features that are essential for increasing productivity on boring mills, VTLs, milling machines and long travel lathes. Built with the operator in mind, the DP1200 includes large, clear numerical displays and an intuitive color TFT message screen along with an optional DSU.

- Available in 2, 3 or 4 axes (inlcuding rotary / angular)

- Clean, Crisp, Extra Large, LEDs

- 3.5″ TFT LCD diplay – high density, high contrast

- User Definable Axis Legends

- Solid Cast Construction

- Long Life Membrane Keypad

- Safe, Low Voltage Power Supply (UL)

- Panel Mount Version Available

DP1200 Features Include:

- Real-Time Tool Path Graphics

- Auto-Zoom

- Feed Rate Display

- Bolt Hole Circle Routine

- Line Hole Routine

- Arc Contouring

- Programmable Memory/Teach

- Polar Coordinate Readings

- Tool Offsets

- Taper Calculations

- Axis Vectoring/Summing

- Linear and Segmented Error Comp.

- Skew

- RS232 Output

- Languages: English, French, German, Spanish, Italian, Turkish, Czech, Russian, Portugues, Danish

Downloads

DP1200 Data Sheet

DP1200 Quick Start Guide

DP1200 Operators Manual

The NEWALL DP700 is the latest in Newall’s line of a powerful and intuative DROs. The unit is housed in a rugged, ergonomically designed casting. The DRO features all of the essential functions for milling, boring, turning, grinding, and general machining operations

- Available in 1, 2 or 3 axes

- Clean, Crisp, Easy to Read, LEDs

- Intuitive Message Window

- Long Life Membrane Keypad

- Solid cast construction

- Safe, Low Voltage Power Supply (UL)

- Panel Mount Version Available

DP700 Features Include:

- Feed Rate Display

- Bolt Hole Circle Routine

- Line Hole Routine

- Arc Contouring

- Programmable Memory/Teach

- Polar Coordinates

- Tool Offsets

- Taper Calculations

- Axis Vectoring/Summing

- Linear and Segmented

- Error Comp.

- Undo

- RS232 Output

- Languages: English, French, German, Spanish, Italian, Turkish, Czech, Russian, Portugues, Danish

The Newall NMS800 is the newest in Sensata | Newall’s range of premium readouts. The DRO hosts many productivity enhancing features that will increase machine tool efficiency.

The NMS800, when matched with Sensata | Newall’s Spherosyn Serial and Microsyn Serial encoders, provides years of maintenance free, trouble free performance. Sensata | Newall’s inductive encoders are simple to install and designed to provide consistent accuracy and reliability even under the harshest workshop conditions.

Features

- Available in 2, 3, or 4 axes

- Clean, crisp PMVA LCD display

- Self-sensing encoder input

- Long life membrane keypad

- Linear and angular reading (model dependent)

- Safe, low voltage power supply (UL)

- Panel mount version available

Other features

- Feed rate display

- Bolt hole circle routine

- Line hole routine

- Arc contouring

- Programmable memory / teach

- Polar coordinates

- Tool offsets

- Taper calculations

- Axis vectoring / summing

- Linear and segmented error compensation

- Undo function (move back up to eight steps if a mistake is made)

- RS232 output

- Multiple languages

Downloads

Spherosyn™ and Microsyn™ encoders are designed to give you consistent accuracy and reliability under even the harshest shop conditions. Based on the principle of electromagnetics, Newall’s analogue encoders embody a truly innovative design in which all of the electronic and measuring components are sealed and protected. The encoders carry an IP67 (NEMA 6) environmental rating and will continue to provide accurate and reliable readings even when submerged in water, oil and coolant.

Encoder Benefits

- IP67 (NEMA 6)

- Withstands dust, dirt, oil and other environmental conditions

- No mechanical wear characteristics

- Requires no cleaning or maintenance

- High tolerance to shock and vibration

Consistent accuracy and reliability even under the most extreme shop conditionsDesigned to work exclusively with Newall’s digital readouts, the Spherosyn™ and Microsyn™ encoders embody a truly innovative design in which all of the electronics and measuring components are sealed and protected. The encoders carry an IP67 environmental rating and will continue to provide accurate, reliable readings even when fully submersed in water, oil or coolant. No other linear encoder matches the durability and reliability of Newall’s reader heads and scales.

How it works: Click here to download

Incredibly powerful, yet incredibly easy to use. From the company that revolutionized the DRO industry comes yet another breakthrough in performance and functionality. Newall`s DP900 offers unsurpassed features in an easy to use package that will increase your machine tool efficiency.

Stability throughout the rugged shop environment.

Mill, Lathe and Geometric Functionscalculations can be performed without removing the part from the machine.Increase Productivity with Tool Path Verification enables the operator to graphically view the tool.

Spherosyn™ and Microsyn™ encoders are designed to give you consistent accuracy and reliability under even the harshest shop conditions. Based on the principle of electromagnetics, Newall’s analogue encoders embody a truly innovative design in which all of the electronic and measuring components are sealed and protected. The encoders carry an IP67 (NEMA 6) environmental rating and will continue to provide accurate and reliable readings even when submerged in water, oil and coolant.

Encoder Benefits

- IP67 (NEMA 6)

- Withstands dust, dirt, oil and other environmental conditions

- No mechanical wear characteristics

- Requires no cleaning or maintenance

- High tolerance to shock and vibration

Consistent accuracy and reliability even under the most extreme shop conditionsDesigned to work exclusively with Newall’s digital readouts, the Spherosyn™ and Microsyn™ encoders embody a truly innovative design in which all of the electronics and measuring components are sealed and protected. The encoders carry an IP67 environmental rating and will continue to provide accurate, reliable readings even when fully submersed in water, oil or coolant. No other linear encoder matches the durability and reliability of Newall’s reader heads and scales.

How it works: Click here to download