| Supply voltage with surge protection |

Universal with mains input range between 100 V and 264 Vac (±10%); Frequency 45Hz to 400Hz |

| Working temperature | From 5ºC to 45ºC (from 41ºF to 113ºF) |

| Storage temperature | From -25ºC to 70 ºC (from -13ºF to 158ºF) |

| Relative humidity | Maximum 95% non condensing 45ºC (113ºF) |

| Seal | Front panel IP54 and rear panel, IP4X (DIN 40050) |

| This product meets the Safety and Electromagnetic Compatibility regulations |

EN-60204-1, EN-50081-2, EN 55011, EN-55022, EN-50082-2, EN-610004-2, 3, 4, 5, 6, 11, EN-V50140, EN-V50141, ENV 50204 and European Union regulations 73/23/ECC, 89/392/CEE, 89/336/ECC and 73/23/EEC |

| Feedback signal type | TTL 0-5 VDC ±5% • Differential TTL 0-5 VDC ±5% • Only on models ending in "1": Voltage modulated differential sinusoidal 0-5V (1Vpp + 20%-40% with a load of 120 Ohm) • Other signal types through an adapter (consult) |

| Maximum feedback signal frequency |

250 KHz |

Blog Archives

Fagor NVP 200

The “NVP 200/201 QC” makes it possible to turn a simple profile projector or microscope into a powerful automatic measuring (fiber optic) and 2D calculating machine.

As well as offering basic measurement and calculation features for lines, circles, distances and angles, the NVP 200 QC also offers powerful features such as:

- Tolerance control

- Statistic process control of

a series of measurements - Optionally: fiber optic

connection

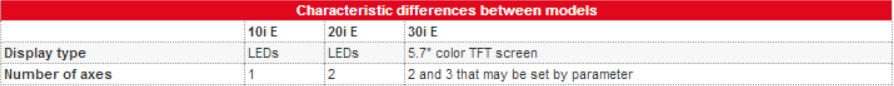

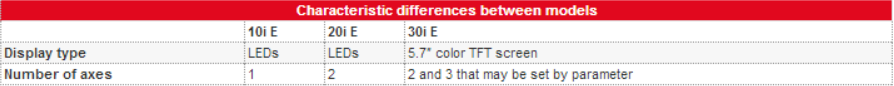

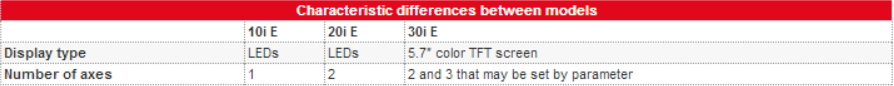

Fagor-10i-E

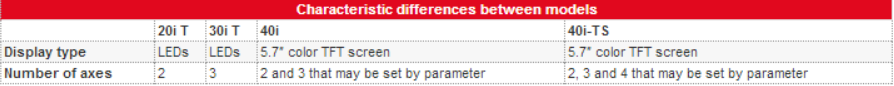

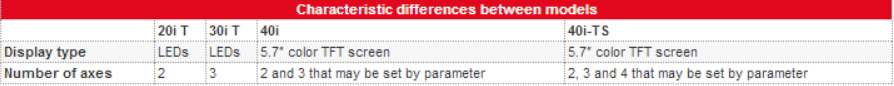

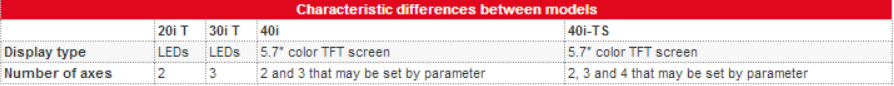

Fagor-20i T

2-axis DRO for lathes: Innova 20i T

Preset function

Preset function- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Taper calculation

- Z axis coupling

- Up to 20 tool references

- Preset in HOLD mode

- CE and UL certified

Fagor-20i-E

Fagor-30i T

3-axis DRO for lathes: Innova 30i T

Preset function

Preset function- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Taper calculation

- Z axis coupling

- Up to 20 tool references

- Preset in HOLD mode

- Axis feedrate display

- CE and UL certified

Fagor-30i-E

Fagor-40i-TS

DRO for up to 4 axes lathes: Innova 40i-TS

Preset function

Preset function- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Taper calculation

- Turning

- Facing

- Assisted threading (easy threading)

- Z axis coupling

- Up to 100 tool references

- Preset in HOLD mode

- Go to a particular position

- Axis feedrate display

- On-screen guided help, with graphics

- CE and UL certified

- 5.7″ color TFT screen

- Constant Surface Speed (CSS)

- Special inputs: Emergency input, analog input for the potentiometer, external push buttons (M3, M4, Stop, etc.)

- Analog and digital outputs

- It admits an encoder at the spindle

Fagor-Innova 20i

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Taper calculation

- Z axis coupling

- Up to 20 tool references

- Preset in HOLD mode

- CE and UL certified

Fagor-Innova 30i

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Bolt-hole drilling

- Linear drilling calculation

- Tool radius compensation

- Part centering

- Up to 20 tool references

- Part alignment

- Corner rounding/machining of arcs

- CE and UL certified

Fagor-Innova 40i

DRO for grinders and general purpose applications: Innova 40i

Preset function

Preset function- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Go to a particular position

- Axis feedrate display

- On-screen guided help, with graphics

- CE and UL certified

- 5.7″ color TFT screen

Heidenhain ND 780 series

The ND 780 digital readout is especially suited for use on milling, drilling and boring machines and lathes with up to three axes. A separate I/O unit provides switching

input/outputs for simple tasks in automation.

Design

The ND 780 digital readout is designed as a sturdy upright unit with splash-proof fulltravel keypad for use in a workshop. It is equipped with a monochrome fl at screen for position values, dialog and input displays, graphic functions and graphic positioning support.

Functions

The ND 780 readout is characterized by its plain language dialog guidance. The distance-to-go display facilitates positioning. You approach the next position quickly and reliably by simply moving until the display reads “zero”. The functions for each application are easily activated by parameter input. Special functions are available for producing hole patterns (linear patterns and circular patterns). Datums can be determined quickly and accurately with an edge fi nder. The ND 780 readout supports you with special probing

functions.

You can easily switch between radius and diameter display when the position display is confi gured for turning. The readout also offers support for lathes with separate top

slide: The sum display feature allows you to display the saddle and top slides together or separately. To set a datum, touch the workpiece and freeze the tool position. Then retract and measure the workpiece.

Data interfaces

The ND 780 has an RS-232-C/V.24 serial interface for measured value transfer to a PC or printer, for input/output of parameters and compensation value lists, and for diagnostics.

6 digital output

6 digital output