Linear Encoders

Fagor Automation uses two measuring methods in their absolute linear encoders:

• Graduated glass: Linear encoders with a measuring length of up to 3040 mm.

• Graduated steel: Linear encoders with a measuring length over 3040 mm.

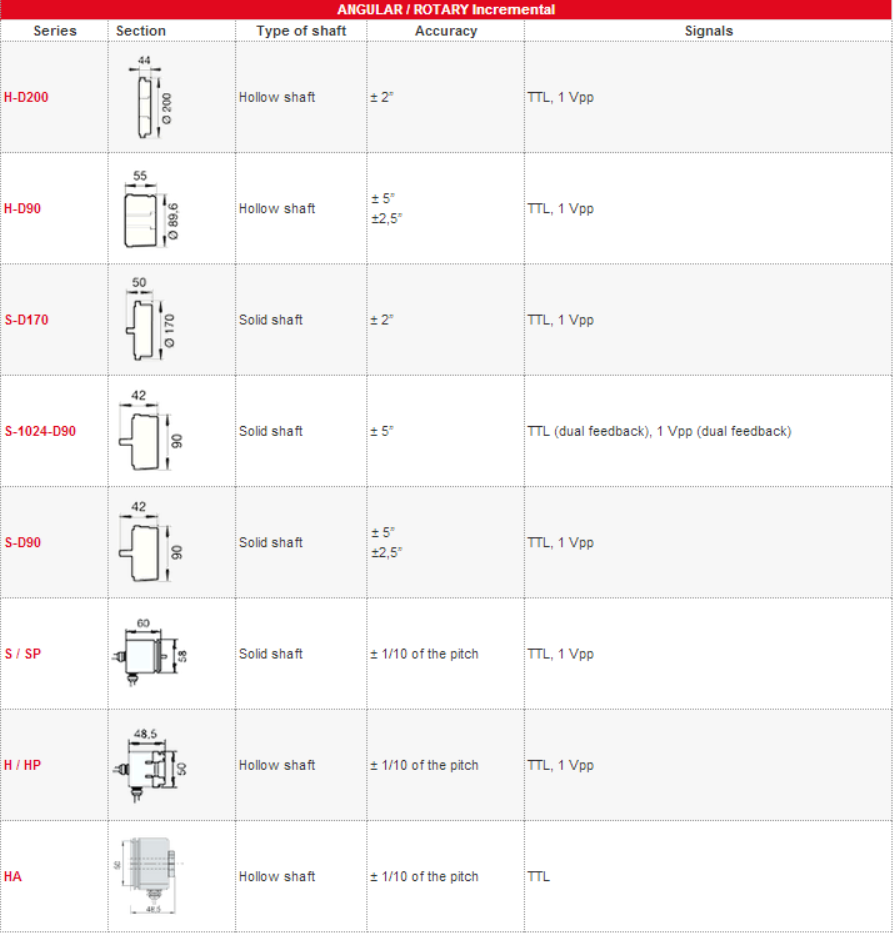

Angular and Rotary Encoders Fagor Automation uses the graduated glass measuring method in their absolute angular and rotary encoders.

This measuring method has two different graduations:

• Incremental graduation: Used to generate square incremental signals for systems that use digital position input and are counted internally by the reader head. Alternatively 1 Vpp analog signal is also produced based on the system requirement.

• Absolute graduation: It is a unique binary code which is imprinted along the measuring length of encoder.